some more progress...

for quite a while now i`ve wanted to get rid of the cross bulkhead braking system on my RHD car.. so ive been looking at bias pedal box solutions..

before spending any cash i made a mock up of the master cylinders to have a look for space....

ok... i dont like to be beaten.. and i really dont like the 106 brake linkage...

following on from Sandys comments about a overhung bias assembly being preferable i had a quick look to see what space was like above the steering colomn:

"the man from DelMonte.... he say YES!!"

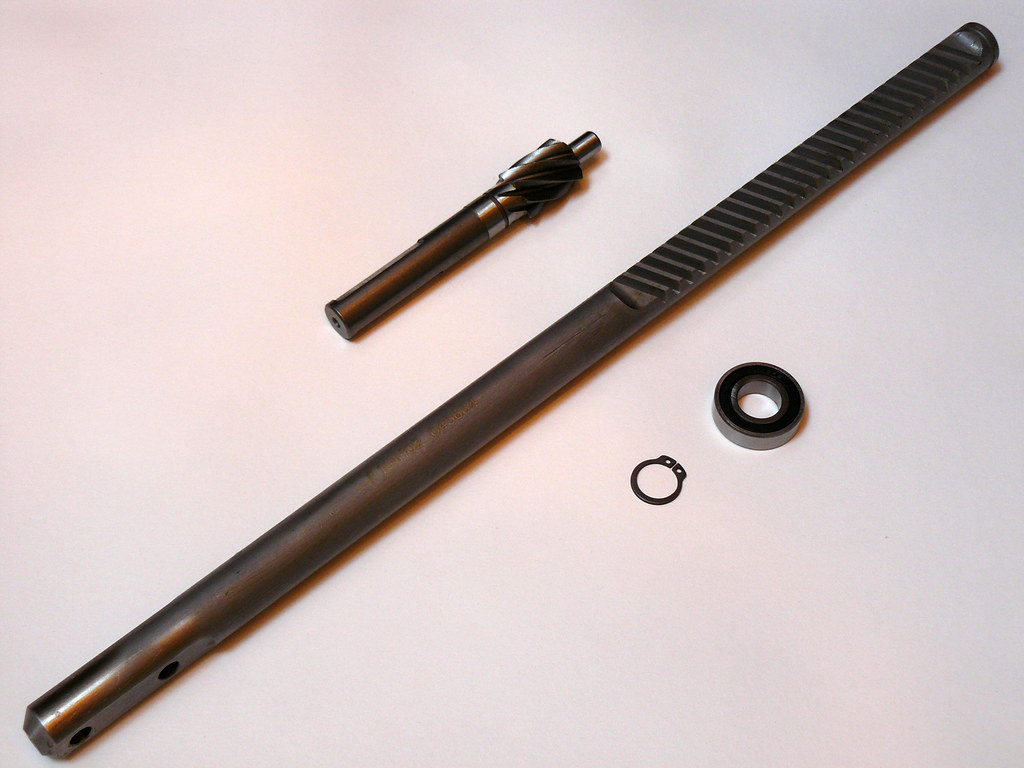

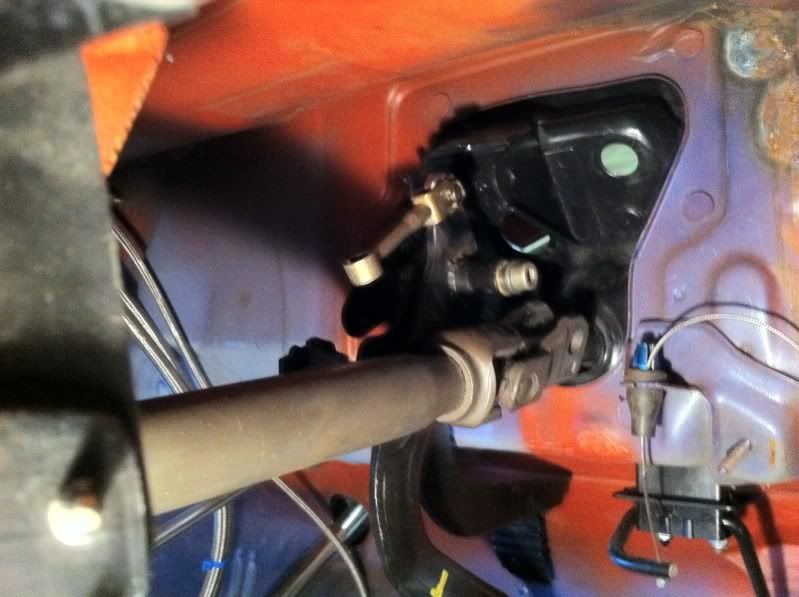

so off with the rack.. off with the pedal assembly:

as you can (just about) see.. the clutch pedal (closest) pivots and the upper portion of the pedal pulls the clutch cable... the brake pedal pivots at the top and pushes a actuator through the bulkhead which in turn operates the cross link...

now... if the assembly could be modified so the clutch AND brake pedal shared a common pivot point and instead of using a "pull" motion like the clutch does the brake pedal "pushes" towards the back of the clocks area,, we may, in fact, have a winner!!

so thats what i did!!:

still need to fabricate a support for the pivot bolt as you can see but the idea seems to work...

ive also measured from the new pivot to the pedal pad and positioned the pushrod so it operates with a 6:1 pedal ratio...

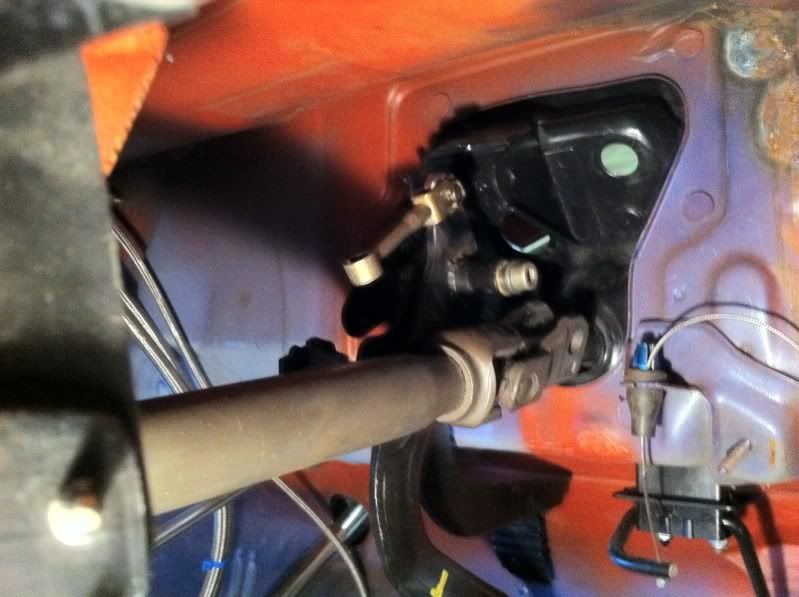

a quick trial fit:

as you can see the steering knuckle is close to the pivot bolt but i can mod a few things and have a safe clearance easy enough....

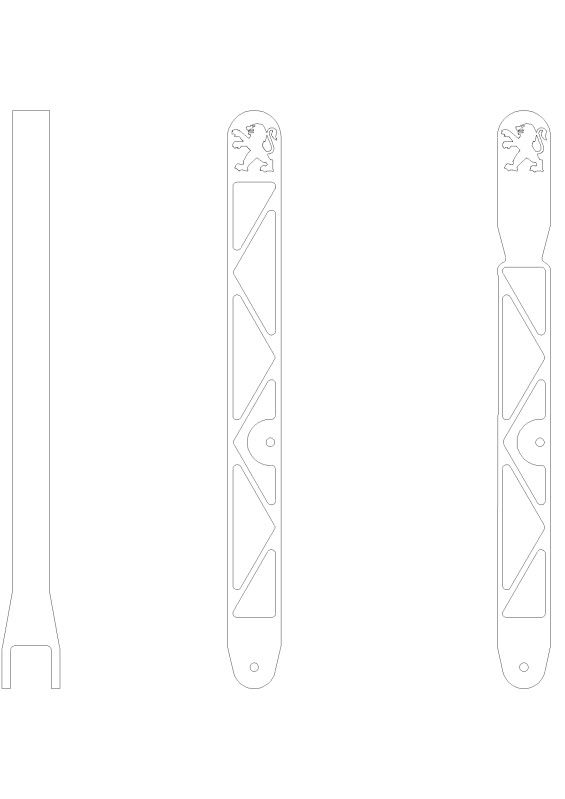

as you can see the pivot point for the brake pedal has moved and a 3mm thick pickup made for the clutch and brake pedals to share.. a new 3mm outer plate has been made that not only supports the clutch pivot but also supports the master cylinders.. a piece now needs to be made to:

*support the brake pedal pivot

*clear the steering knuckle

*clear the throttle cable

*support the backplate that holds the master cylinders...

hmmm could be a tricky bastard!!!!

the big side plate needs a window cutting in to allow clearance for the bias bar...

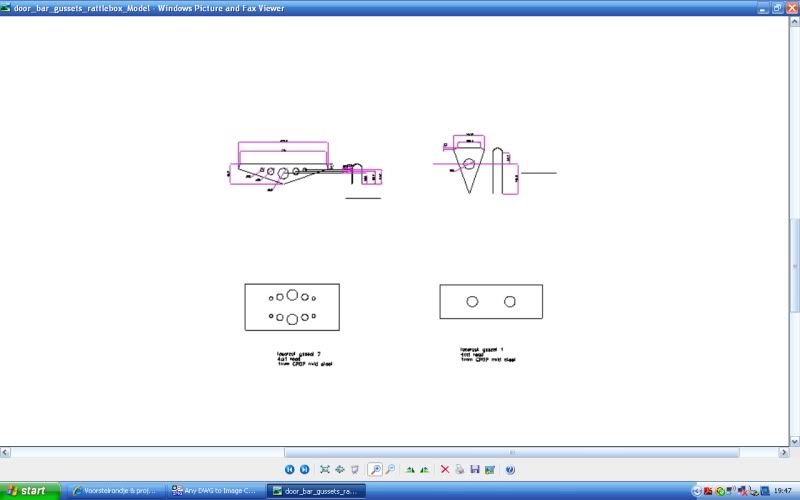

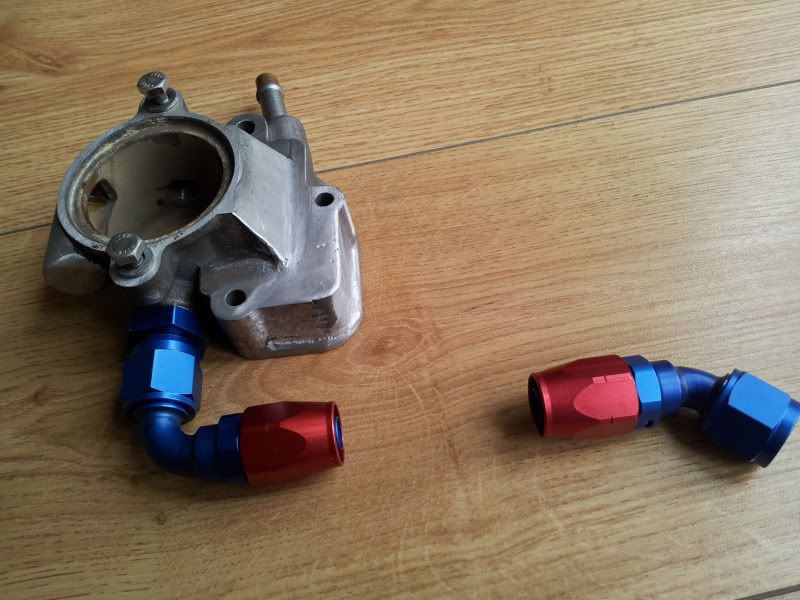

an some geeky shit... feel free to ignore...

with the ideal pedal ratio of 6:1 acheived, due to the limited length of the peugeot pedal the short arm that operates the cylinders is quite short and that causes some issues..

1- suitable stroke.. pedal moves a lot but the arm only moves 1/6th of the distance..

2- the arc that the upper pivot is quite a tight radius that means as the arm moves towards the master cylinders it travels up and down (imagine 1 of those knobs on a steering wheel..)

1- according to the AP site the cylinders i plan to use have a 1" stroke.. 6" of foot travel?? meh.. should still be way off the floor i reckon...

2- also.. according to the AP site the maximum angle the pushrods can go through is 4degrees.. from a few more measurements i think theres about 40mm of travel before that angle is exceeded...

so... basically... it should work.....

http://www.apracing.com/info/products.asp?product=Vertical+Flange+Types+%3Cimg+border%3D%222%22+src%3D%22http%3A%2F%2Fwww%2Eapracing%2Ecom%2Fpics%2Fproductpics%2FFlange%2520Mount%2Ejpg%22%2F%3E%2DCP2623+Type_2386_2385